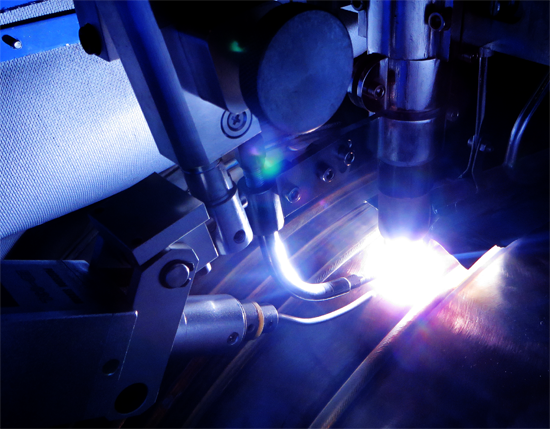

Getweld Automatic MIG Longitudinal seam welders are designed for small to large-scale straight welding applications.These machines commonly function to weld seams at the outside surface of tanks. Esp. for liquefied petroleum gas (LPG) cylinder, liquefied natural gas (LNG) cylinder, porcelain enamel tank and large scale cryogenic storage tank. MIG welding has highlight advantages, such as high density of current, strong penetrability, smooth welding quality. 5mm SS sheet could be full-penetration welded without groove.

Fill out my online form.